An extensive needs analysis is key to ensuring the ideal technology for any optimised medical grade compressed air system. The design of a compressed air system for medical use must be geared to meet the need every time.

Even in the medical sector, a compressed air system has to be cost-effective, including ensuring low installation and low operating costs. Highly efficient energy-saving technologies combined with dryers, filtration, control monitoring, and display concepts provide seamless interaction between all system components.

MEDICAL COMPRESSOR USES IN MEDICAL APPLICATIONS

Compressed air is used for assisted breathing in medical devices. This would be a medical air compressor package that has specific code requirements per NFPA 99. Clean, dry safe air needs to be delivered to the patients quickly on demand.

Compressed air is used in other areas of a hospital for physical therapy, laboratory use, central sterile processing, and to power air tools. Medical compressors are an absolute necessity to the medical industry.

When determining the best technology to choose for your specific healthcare facility application, there are a set of questions that should be answered. These questions are not all-encompassing, but they will help guide you down the path of choosing the correct technology best suited for the client.

- What does the demand profile look like? Will it be constant or have high/low peaks?

- What’s the budget criteria? Are they willing to invest upfront?

- How will maintenance be practiced? Internally or by an outside service provider?

- Are there any plans for future expansion?

- Are energy savings and consumption considerations in effect?

- What about the sustainability of the facility?

Coupled with ever-changing Health and Safety regulations and legislation, the medical industry can rely on specially designed Pattons Medical compressed air equipment to provide the perfect solutions for your compressed air demands.

Let’s start by reviewing the Pros and Cons of the different types of technologies available for the medical air systems.

ROTARY SCROLL COMPRESSOR

Rotary Scroll Compressors are equipped with intermeshing spiral scrolls and aftercoolers, making them perfect for continuous medical application with minimum noise levels. An enclosed scroll system offers the advantage of reduced noise levels. It also permits ducting in cooling air and exhausts the hot air. These compressors are compact, demanding lower footprint requirements. They are low maintenance. However, it should be remembered that these compressors need annual maintenance. They have a lower air end life when compared to the reciprocating compressors and lower SCFM per output. In short, they have a lower operating costs and extended service intervals.

An oil-less scroll compressor does not generate excess heat and they offer reliability even after completing their full duty cycle.

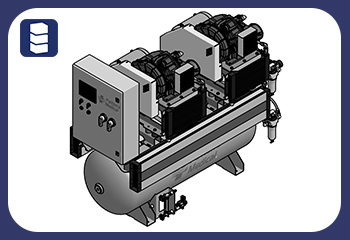

RECIPROCATING COMPRESSOR

A Reciprocating compressor long-life pistons. They are robust, having around 30K to 50K hours of life. They are cost-effective per HP. They are flexible and allow for intermittent cycles.

However, they require a large footprint and have a noise level that may reach up to 84db. They require quarterly maintenance of their belts and pistons, which will result in temporary shutdown or malfunction once worn out.

A Reciprocating Compressor is used wherein interruption in operation does not harm the patient directly. They can be ranked as Category 3 Care Devices.

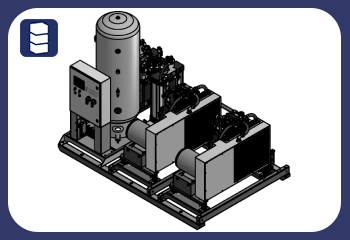

ROTARY SCREW COMPRESSORS

Oil-free rotary screw compressors are robust, having a long-life air end. The rate of SCFM output per HP is higher. They operate in minimum noise levels. They are best suited for applications requiring a higher SCFM output greater than 300.

However, rotary screw compressors occupy a large footprint. They are costlier when compared to the scroll compressors. Specialist maintenance personnel is required and the cost per maintenance interval is also higher.

The following chart shows the variable costs per SCFM, Life Span, Noise dB, Energy Consumption.

| Technology | Cost($/CFM) | Life Span(hours) | Noise | Maintenance Cost | Energy Consumption (CFM/HP) | Additional Considerations |

|---|---|---|---|---|---|---|

| Reciprocating | 798.5 | 20,000+ | 84 dB | High | 3.5 | What is facility capabilities? |

| Scroll | 729.2 | 10-20,000 | 73dB | Low | 3.2 | What is facility capabilities? |

| Screw | 789.1 | 30,000 | 69dB | Medium | 4.2 | Environmental Consideration |

DRYERS

Regardless of application or compressor type, you will need to also have a dryer to remove the water from the airlines. For medical air packages, NFPA 99 code requires a desiccant dryer. For laboratory or non-medical, a refrigerated dryer is acceptable. Choosing a package with a desiccant dryer a demand-based purge allows the dew point to determine when the dryer purges. The compressor will only run based on demand and not to just the purge the dryer, keeping the hours down. Pattons Medical desiccant dryer utilizes desiccant cartridges making it incredibly easy to change out.

THE BEST TECHNOLOGY FOR YOUR FACILITY

In conclusion, each healthcare application may have intricacies based on the space available or location elevation for the medical gas systems. Whether you’re designing a new facility or renovating an existing building, you’ll find the basic questions will be beneficial to your technology selection.

Pattons Medical has a team of medical gas consultants and engineers who are experienced in the technology selection. Please give us a call early in your project and we would be happy to guide you in the medical gas design.