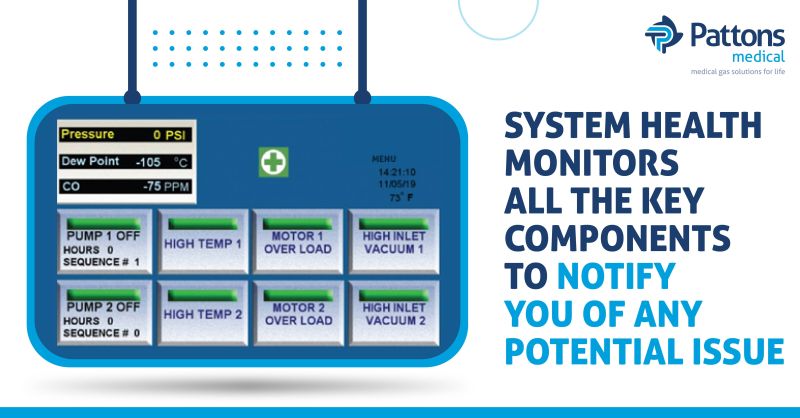

Keeping your medical gas equipment performing is critical. That is why Pattons Medical offers a System Health standard feature for all of our air compressor and vacuum pump systems for medical and laboratories. Using the HMI that comes on all control panels, we give you the ability to constantly track information on the systems’ performance and the ambient conditions. As a result, we can alert you of any issues before a system failure. Here are some key trends the System Health monitors to ensure your system runs healthy:

AMBIENT TEMPERATURE

Monitoring ambient temperature is important because, if the temperature is cold, there is the chance that the unit might not start. If the temperature is hot, grease can break down faster, causing premature failure of a major component. Our sensor has a range of 32°F-122°F. By monitoring the temperature, we can inform the customer of an environmental issue that can cause damage to the unit.

CURRENT

System Health can monitor the current drawn by the machine to notice if a component is starting to fail. If bearings (in the motor or pump) fail, the motor draws more current than normal for some time before breaking down. By monitoring the current, we can inform the customer of a pump bearing failure before the actual failure. If caught early, maintenance of the bearings may save the component.

DEW POINT

The standard dew point range is -10°C to 2°C. If the dew point gets to -3°C, the System Health icon will flash on the screen to notify the operator. It will also be documented in the History Log and can be seen in the Trending data. In case of an alert, the unit should be checked for a possible dryer service or dew point sensor malfunction/failure.

CARBON MONOXIDE

System Health can monitor Carbon Monoxide (CO) levels as per NFPA99. The maximum CO allowance is 10ppm. The System Health icon will flash on the screen when the CO level reaches 7ppm as it is an indicator that there could be an issue with the CO monitoring device or there is an actual CO source near the intake.

PUMPS RUNNING

System Health can track LAG pump activity. This allows you to see the history of how many pumps have been running and for how long. If the value increases, it might be a leak in the system or some other issue. System Health gives you trending data to help identify issues and also allows you to see how close you are coming to activating the LAG pump.

PRESSURE/VACUUM

System Health can give you a reference to the cycling time and variation on how the pumps are running and maintaining the pressure/vacuum. By combining this trend along with the pump running trend, we can provide the customer with an overall assessment of the system and how well it is operating.

For more information on our System Health feature, contact your local medical/laboratory gas consultant. Click below